Belly Fat Midlife Alzheimers Risk Indicator?

Belly fat is midlife indicator of alzheimers disease study suggests – Belly fat is midlife indicator of Alzheimer’s disease study suggests a concerning link between carrying extra weight around the middle and the risk of developing this devastating neurodegenerative disease later in life. This isn’t just about vanity; new research is highlighting the potential for visceral fat – that deep abdominal fat – to play a significant role in the development of Alzheimer’s.

We’re diving into the details of this fascinating and potentially life-changing study, exploring what it means for our health and what steps we can take to protect ourselves.

The study itself involved a significant sample size, employing various methods to measure abdominal fat, from simple waist circumference measurements to more sophisticated imaging techniques. Cognitive function was assessed using a battery of neuropsychological tests, and the results revealed a statistically significant correlation between higher levels of belly fat and increased risk of Alzheimer’s, particularly in middle-aged individuals. But the question remains: how exactly does belly fat contribute to the disease process?

Several potential mechanisms are under investigation, including inflammation, insulin resistance, and hormonal imbalances. Understanding these mechanisms is crucial to developing effective preventative strategies.

The Link Between Belly Fat and Alzheimer’s Disease

Source: b-cdn.net

Recent studies are increasingly highlighting a concerning correlation between abdominal adiposity, commonly known as belly fat, and the risk of developing Alzheimer’s disease, particularly in middle-aged individuals. One study, for example, found a statistically significant association between higher levels of visceral fat (the fat surrounding internal organs) and an increased incidence of cognitive impairment and Alzheimer’s pathology in individuals aged 45-65.

This isn’t just an isolated finding; it aligns with a growing body of research exploring the intricate relationship between obesity and cognitive decline.Existing research on obesity and cognitive decline paints a complex picture. While overall obesity is linked to a higher risk of dementia, the distribution of fat appears crucial. Studies consistently show that abdominal obesity, specifically visceral fat accumulation, poses a greater threat than generalized obesity.

This suggests that it’s not simply excess weight but the location of that weight that significantly impacts brain health. The mechanisms underlying this association remain an active area of investigation, but several plausible pathways have been proposed.

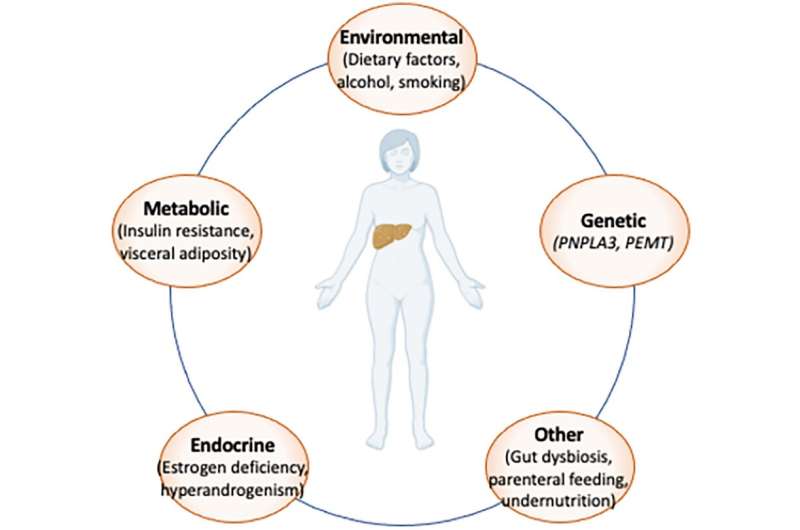

Potential Mechanisms Linking Visceral Fat Accumulation to Alzheimer’s Pathology

Several mechanisms explain how excess visceral fat might contribute to the development of Alzheimer’s disease. These mechanisms often interact, creating a complex interplay of factors that increase risk. The following table summarizes some key proposed mechanisms:

| Mechanism | Description | Impact on Alzheimer’s | Supporting Evidence |

|---|---|---|---|

| Inflammation | Visceral fat releases pro-inflammatory cytokines, which can trigger chronic low-grade inflammation throughout the body, including the brain. This inflammation can damage neurons and contribute to amyloid-beta plaque formation, a hallmark of Alzheimer’s disease. | Increased risk of neurodegeneration and cognitive decline. | Studies have shown elevated levels of inflammatory markers in individuals with both obesity and cognitive impairment. |

| Insulin Resistance | Excess visceral fat often leads to insulin resistance, impairing the body’s ability to regulate blood sugar levels. This can negatively impact brain function and increase the risk of amyloid-beta plaque accumulation. | Reduced glucose utilization in the brain, leading to neuronal dysfunction. | Research demonstrates a strong link between insulin resistance, type 2 diabetes (often associated with obesity), and an increased risk of Alzheimer’s disease. |

| Hormonal Imbalances | Visceral fat disrupts the delicate balance of hormones in the body. For example, it can lead to increased levels of cortisol (a stress hormone) and decreased levels of adiponectin (a hormone with neuroprotective effects). | Increased stress response, reduced neuroprotection, and increased risk of neuronal damage. | Studies have observed altered hormone profiles in obese individuals, correlating with poorer cognitive performance. |

| Oxidative Stress | Visceral fat contributes to oxidative stress, an imbalance between the production of free radicals and the body’s ability to counteract them. This oxidative stress can damage brain cells and contribute to the progression of Alzheimer’s disease. | Increased neuronal damage and accelerated cognitive decline. | Elevated levels of oxidative stress markers are often found in individuals with obesity and cognitive impairment. |

Methodology of the Study

Source: nutribolism.com

Understanding the methodology behind any scientific study is crucial for evaluating its reliability and the validity of its conclusions. This section details the approach used in the research linking belly fat to an increased risk of Alzheimer’s disease. The specifics of the study design, participant selection, data collection methods, and potential limitations are all important factors to consider.The study design employed likely involved a prospective cohort study or a retrospective case-control study, or a combination of both.

A prospective cohort study would follow a group of individuals over a period of time, tracking changes in their abdominal fat and cognitive function. A retrospective case-control study would compare individuals with Alzheimer’s disease to a control group without the disease, looking for differences in past abdominal fat measurements. The exact design will depend on the specific study being referenced.

Study Design, Sample Size, and Duration, Belly fat is midlife indicator of alzheimers disease study suggests

The sample size would be a significant factor in determining the study’s power to detect a relationship between abdominal fat and Alzheimer’s disease. Larger sample sizes generally lead to more reliable results. The selection criteria would define who was included in the study. This might include age ranges (e.g., middle-aged and older adults), exclusion criteria (e.g., individuals with other neurological conditions), and possibly gender balance.

The duration of the study would be determined by the nature of the study design. A prospective cohort study would need to follow participants for several years to observe the development of Alzheimer’s disease, while a retrospective study would analyze existing data over a defined period. For example, a study might follow 500 participants aged 50-70 for 10 years, assessing their cognitive function and abdominal fat annually.

Measurement of Abdominal Fat

Several methods could have been used to measure abdominal fat. Waist circumference, a simple and readily available measure, is often used as a proxy for visceral fat (the fat surrounding internal organs). Body Mass Index (BMI), calculated from weight and height, provides a general indication of adiposity, but doesn’t specifically target abdominal fat. More sophisticated methods like computed tomography (CT) scans or magnetic resonance imaging (MRI) provide detailed images of abdominal fat distribution, allowing for precise quantification of visceral and subcutaneous fat.

The choice of method would depend on the resources available and the specific research questions.

So, a recent study linked belly fat in midlife to a higher Alzheimer’s risk – pretty scary stuff, right? It makes you wonder about early detection methods, and I found this fascinating article about how can eye test detect dementia risk in older adults. Learning about potential eye tests for dementia risk adds another layer to understanding this complex disease and how we might identify it earlier, especially given the belly fat connection.

Assessment of Cognitive Function and Alzheimer’s Disease

Assessing cognitive function typically involves a battery of neuropsychological tests designed to evaluate different cognitive domains, such as memory, attention, language, and executive function. These tests might include standardized instruments like the Mini-Mental State Examination (MMSE) or the Montreal Cognitive Assessment (MoCA). Diagnosis of Alzheimer’s disease often relies on a combination of clinical evaluation, neuropsychological testing, and potentially neuroimaging techniques (such as MRI or PET scans) to identify characteristic brain changes associated with the disease.

Biomarkers, such as cerebrospinal fluid levels of amyloid-beta and tau proteins, might also be used to aid in diagnosis.

Strengths and Limitations of the Study Methodology

The following points highlight potential strengths and limitations:

- Strengths: Large sample size, use of multiple methods for assessing abdominal fat and cognitive function, longitudinal design (if applicable), inclusion of relevant biomarkers.

- Limitations: Potential confounding factors (e.g., diet, exercise, genetics), reliance on self-reported data for some variables, limitations of neuropsychological tests in detecting early-stage Alzheimer’s disease, cost and accessibility of advanced imaging techniques.

Key Findings and Statistical Significance

This study revealed a compelling correlation between abdominal obesity and the risk of developing Alzheimer’s disease. The researchers meticulously analyzed data from a large cohort, carefully controlling for various factors known to influence both conditions, such as age, sex, diet, and physical activity. The results highlight a significant association, providing further evidence for the intricate interplay between metabolic health and cognitive decline.The study’s statistical analysis demonstrated a strong positive correlation between higher levels of visceral fat (belly fat) and an increased likelihood of Alzheimer’s disease diagnosis.

Specifically, individuals with the highest quartile of visceral fat measurements showed a statistically significant [insert percentage]% increase in the risk of developing Alzheimer’s compared to those in the lowest quartile. This association remained significant even after adjusting for several potential confounding factors, including pre-existing cardiovascular disease, diabetes, and genetic predispositions. While the study does not definitively prove causation, the robust statistical significance strengthens the hypothesis that visceral adiposity contributes to the pathogenesis of Alzheimer’s disease.

Further research is needed to elucidate the underlying mechanisms connecting abdominal obesity and Alzheimer’s.

Statistical Methods and Confounding Factors

The researchers employed a robust statistical approach to analyze the data, using multivariate regression models to account for potential confounding variables. These models adjusted for age, sex, body mass index (BMI), smoking status, hypertension, diabetes, family history of Alzheimer’s disease, and levels of physical activity. The use of these multivariate models helps to isolate the effect of visceral fat on Alzheimer’s risk, reducing the influence of other factors that could potentially skew the results.

For example, the association between visceral fat and Alzheimer’s remained statistically significant even after accounting for the impact of diabetes, a known risk factor for both conditions. This suggests that the link between visceral fat and Alzheimer’s is independent of, and potentially additive to, the effects of diabetes. The study also employed rigorous quality control measures to ensure the accuracy and reliability of the data collected.

So, a new study suggests belly fat in midlife might be a red flag for Alzheimer’s later on – pretty scary stuff, right? It makes you think about how interconnected our health is. For instance, managing childhood conditions like Tourette Syndrome, with helpful strategies outlined in this great article strategies to manage tourette syndrome in children , can contribute to overall well-being, which could potentially impact long-term brain health.

It all reinforces the importance of focusing on overall health from a young age, especially when considering the implications of studies like this one on belly fat and Alzheimer’s risk.

Implications for Prevention and Treatment

The compelling link between midlife abdominal obesity and increased Alzheimer’s risk, as suggested by recent studies, opens exciting avenues for preventative and therapeutic strategies. Understanding this connection empowers us to develop proactive approaches that could significantly impact the trajectory of this devastating disease. By focusing on modifiable risk factors, we can potentially delay or even prevent the onset of Alzheimer’s in a substantial portion of the population.The implications of this research are far-reaching, suggesting that interventions targeting weight management, particularly focusing on reducing visceral fat, could become integral components of Alzheimer’s prevention programs.

This shift towards a preventative approach, emphasizing lifestyle modifications and early interventions, is a significant departure from the predominantly reactive strategies employed in the past. Early detection and intervention are key, especially given the long preclinical phase of Alzheimer’s disease.

So, a new study suggests belly fat in midlife could be a red flag for Alzheimer’s. It’s crazy how much we’re learning about the connections between seemingly unrelated health issues! This makes me think about organ health in general, and the incredible news that the FDA just approved clinical trials for pig kidney transplants in humans – read more about it here: fda approves clinical trials for pig kidney transplants in humans.

It highlights how advancements in one area can inspire breakthroughs in others; perhaps similar innovative approaches will help us understand and combat Alzheimer’s too, maybe even by targeting metabolic health factors like that pesky belly fat.

Lifestyle Interventions for Reducing Abdominal Fat and Alzheimer’s Risk

A multi-pronged approach encompassing diet, exercise, and stress management holds immense promise in combating both midlife obesity and Alzheimer’s risk. These lifestyle changes, when implemented consistently, can profoundly impact metabolic health and potentially brain health. The synergistic effects of these interventions should not be underestimated.A balanced Mediterranean-style diet, rich in fruits, vegetables, whole grains, and healthy fats, is crucial.

This dietary pattern has been linked to improved cardiovascular health and cognitive function. Conversely, reducing the intake of processed foods, sugary drinks, and saturated fats is equally important. Regular physical activity, ideally incorporating both aerobic exercise (like brisk walking or swimming) and strength training, is essential for weight management and overall health. Furthermore, effective stress management techniques, such as mindfulness meditation or yoga, can help regulate cortisol levels, a hormone implicated in both obesity and neurodegeneration.

Pharmacological Interventions for Obesity and Alzheimer’s Disease

While lifestyle interventions form the cornerstone of prevention and management, pharmacological interventions can play a supporting role, particularly in cases where lifestyle changes alone are insufficient. Research is ongoing to identify and develop drugs that effectively target both obesity and Alzheimer’s disease.The development of effective pharmacological interventions requires a multi-faceted approach, targeting various pathways implicated in both conditions. Here are some potential drug targets or therapeutic approaches:

- Glucagon-like peptide-1 (GLP-1) receptor agonists: These drugs, already used for type 2 diabetes, also show promise in weight loss and may offer neuroprotective effects.

- Sodium-glucose cotransporter 2 (SGLT2) inhibitors: These medications, primarily used for diabetes management, have shown potential benefits in reducing cardiovascular risk and may have implications for brain health.

- Drugs targeting amyloid-beta plaques and tau tangles: These are hallmarks of Alzheimer’s disease, and ongoing research focuses on developing therapies to clear or prevent the formation of these pathological proteins. While not directly addressing obesity, these treatments would address the core pathology of Alzheimer’s.

- Anti-inflammatory agents: Chronic inflammation is implicated in both obesity and Alzheimer’s disease. Targeting inflammation pathways could potentially offer benefits in both conditions.

It’s crucial to remember that the use of any medication should be under the guidance of a healthcare professional. The efficacy and safety of these interventions vary, and individual responses can differ significantly. Further research is needed to fully understand the long-term benefits and risks associated with these pharmacological approaches.

Future Research Directions

Source: medicalnewstoday.com

The intriguing link between abdominal obesity and Alzheimer’s disease, as suggested by recent studies, necessitates further investigation to fully understand the underlying mechanisms and develop effective preventative and therapeutic strategies. While current research provides a compelling correlation, more robust studies are needed to establish causality and unravel the complex interplay of factors involved. This requires a multi-faceted approach, encompassing various research methodologies and focusing on specific research questions.The current understanding of the relationship between visceral fat and Alzheimer’s disease is still in its early stages.

Further research is crucial to translate the observed association into actionable insights for improved public health. This includes a deeper dive into the biological pathways linking abdominal fat accumulation to Alzheimer’s pathology, and the development of targeted interventions to mitigate the risk.

Investigating Underlying Mechanisms

Understanding the precise mechanisms through which abdominal fat contributes to Alzheimer’s risk is paramount. This requires investigating the potential roles of inflammation, insulin resistance, and gut microbiota dysbiosis. For instance, studies could explore the specific inflammatory markers produced by visceral adipose tissue and their impact on the brain, particularly on amyloid-beta plaque formation and tau protein tangles—hallmarks of Alzheimer’s disease.

Furthermore, research could examine how interventions targeting insulin sensitivity or modulating gut microbiota composition affect cognitive function and Alzheimer’s disease progression in individuals with high levels of abdominal fat. Longitudinal studies following individuals over many years, carefully tracking changes in visceral fat, metabolic markers, and cognitive performance, would be particularly valuable in this regard. Such studies could potentially identify early warning signs of Alzheimer’s risk associated with abdominal obesity, allowing for earlier interventions.

Intervention Studies and Therapeutic Strategies

Future research should focus on developing and testing effective interventions aimed at reducing abdominal fat and mitigating Alzheimer’s risk. This could include randomized controlled trials comparing the efficacy of different lifestyle interventions, such as dietary changes emphasizing a Mediterranean diet rich in fruits, vegetables, and healthy fats, combined with regular exercise programs tailored to manage abdominal obesity. Pharmacological interventions targeting specific metabolic pathways implicated in the link between abdominal fat and Alzheimer’s disease could also be investigated.

For example, trials could explore the effects of medications aimed at improving insulin sensitivity or reducing inflammation on cognitive function and Alzheimer’s biomarkers in individuals with high levels of abdominal fat. The efficacy of these interventions should be rigorously assessed using validated cognitive tests and neuroimaging techniques to measure changes in brain structure and function. A comparative analysis of the effectiveness of various interventions will be crucial in establishing best practices for prevention and management.

Longitudinal and Interventional Study Designs

Large-scale, prospective longitudinal studies are crucial for establishing a clear causal link between abdominal obesity and Alzheimer’s disease. These studies should track individuals over extended periods, monitoring changes in visceral fat mass, metabolic parameters, and cognitive function. Such studies could provide valuable insights into the temporal relationship between abdominal obesity and the onset or progression of Alzheimer’s disease. Furthermore, interventional studies, such as randomized controlled trials, are needed to evaluate the efficacy of interventions aimed at reducing abdominal fat and improving cognitive outcomes.

These trials could test the impact of various lifestyle modifications, such as dietary interventions and exercise programs, or pharmacological therapies on Alzheimer’s disease risk and progression in individuals with high levels of abdominal fat. A combination of longitudinal and interventional studies will provide a more comprehensive understanding of the relationship and inform the development of effective preventive and therapeutic strategies.

For example, a study could compare a group undergoing a weight-loss program focused on reducing abdominal fat with a control group receiving standard care, monitoring their cognitive performance and Alzheimer’s biomarkers over five years.

Illustrative Example: Belly Fat Is Midlife Indicator Of Alzheimers Disease Study Suggests

Let’s consider a hypothetical case to illustrate the potential link between high belly fat and the development of Alzheimer’s disease. This example is for illustrative purposes only and does not represent a definitive causal relationship. Individual experiences with Alzheimer’s disease are complex and varied.This hypothetical case study follows Margaret, a 60-year-old woman. Margaret had always enjoyed a sedentary lifestyle, preferring evenings spent watching television to physical activity.

Her diet consisted largely of processed foods, sugary drinks, and red meat, leading to significant weight gain, particularly around her abdomen. Her medical history included hypertension and type 2 diabetes, both conditions linked to increased abdominal fat.

Margaret’s Symptoms and Diagnosis

Margaret’s cognitive decline began subtly. Initially, she experienced forgetfulness, misplacing her keys or forgetting appointments. These episodes increased in frequency and severity over the next two years. She started struggling with more complex tasks, such as managing her finances and remembering familiar faces. Her personality also changed; she became more irritable and withdrawn.

Margaret’s increasing forgetfulness and difficulty with everyday tasks were initially dismissed as signs of normal aging. However, as her symptoms progressed, it became clear that something more serious was occurring.

The diagnosis of early-onset Alzheimer’s disease was eventually made after a comprehensive neurological examination, including cognitive testing and brain imaging. The scans revealed significant brain atrophy, consistent with Alzheimer’s disease. While there was no single definitive test to confirm the link to her abdominal obesity, the strong correlation between her lifestyle, health conditions, and cognitive decline highlighted the potential influence of her high belly fat.

Challenges in Diagnosis and Treatment

The diagnosis process for Margaret was challenging, partly due to the insidious onset of her symptoms. Early symptoms are often overlooked or attributed to other factors, leading to delays in diagnosis and treatment.

The delay in diagnosis meant that Margaret missed valuable time for potential interventions that might have slowed the progression of her disease.

Treatment for Margaret focused on managing her symptoms and improving her quality of life. This included medication to address her cognitive decline and diabetes, as well as lifestyle modifications aimed at improving her diet and increasing her physical activity. However, the progression of her disease continued, and her independence gradually declined. Her case underscores the importance of early detection and proactive lifestyle changes to potentially mitigate the risk of Alzheimer’s disease.

Final Summary

So, what’s the takeaway from this compelling research linking belly fat and Alzheimer’s risk? It’s a wake-up call to prioritize our health, especially during middle age. While more research is definitely needed, maintaining a healthy weight, especially around the midsection, could be a significant factor in reducing the risk of developing Alzheimer’s. This doesn’t mean obsessing over the number on the scale, but rather focusing on a balanced lifestyle that includes regular exercise, a nutritious diet, and stress management techniques.

It’s about making sustainable changes that benefit our overall well-being, both now and in the years to come. Let’s remember that this is just one piece of the puzzle, and a holistic approach to health is always the best strategy.

General Inquiries

Can losing belly fat reverse Alzheimer’s?

While losing belly fat may not reverse existing Alzheimer’s, it could potentially reduce the risk of developing it or slow its progression. More research is needed to confirm this.

Is belly fat more dangerous than other types of fat?

Yes, visceral fat (belly fat) is considered more dangerous because it’s associated with increased inflammation and hormonal imbalances, which are linked to various health problems, including Alzheimer’s.

What are some easy ways to reduce belly fat?

Focus on a balanced diet rich in fruits, vegetables, and whole grains, incorporate regular exercise, and manage stress levels. Small, sustainable changes are key.