Can Low Oestrogen Cause Itchiness During Menopause?

Can low oestrogen cause itchiness during menopause? Absolutely! It’s a surprisingly common experience, and understanding why is key to finding relief. Menopause brings a whirlwind of hormonal changes, and the drop in estrogen plays a significant role in how our skin behaves. Think dry, itchy skin, and for some, intense itching in the vaginal area. This isn’t just a minor annoyance; it can seriously impact your quality of life.

Let’s dive into the science behind this frustrating symptom and explore ways to find some much-needed comfort.

This post will explore the connection between declining estrogen levels and the increased incidence of itchiness during menopause. We’ll discuss how estrogen affects skin health, the role it plays in vulvovaginal atrophy (VVA), and other contributing factors that can make the itch even worse. We’ll also cover various treatment options, both hormonal and non-hormonal, to help you find relief and reclaim your comfort.

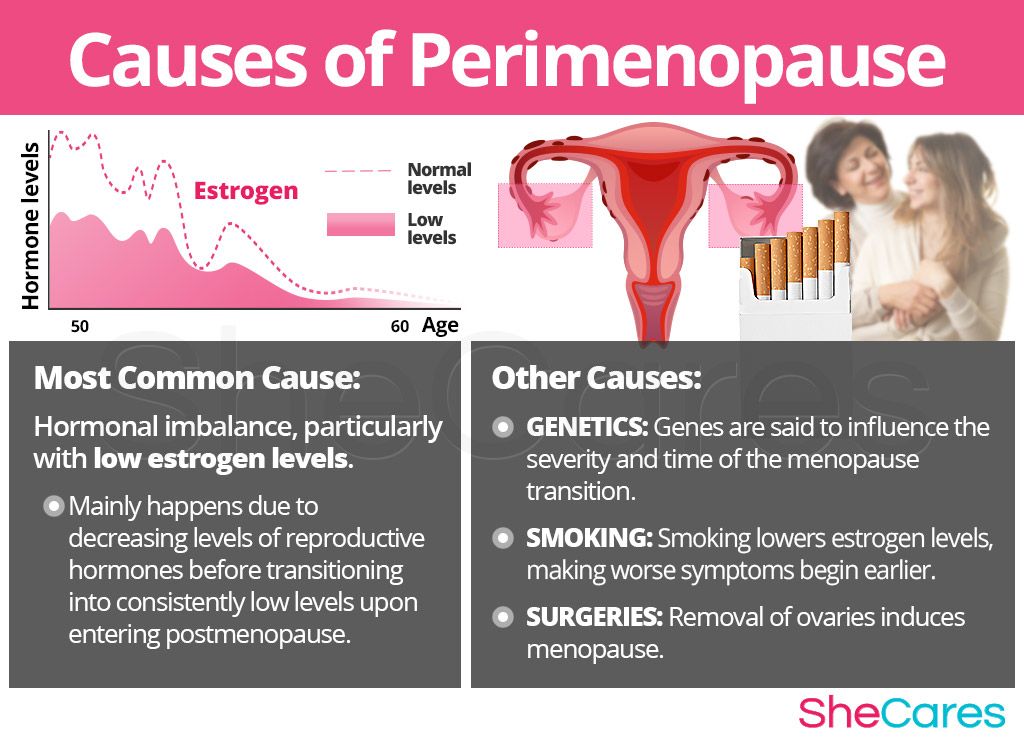

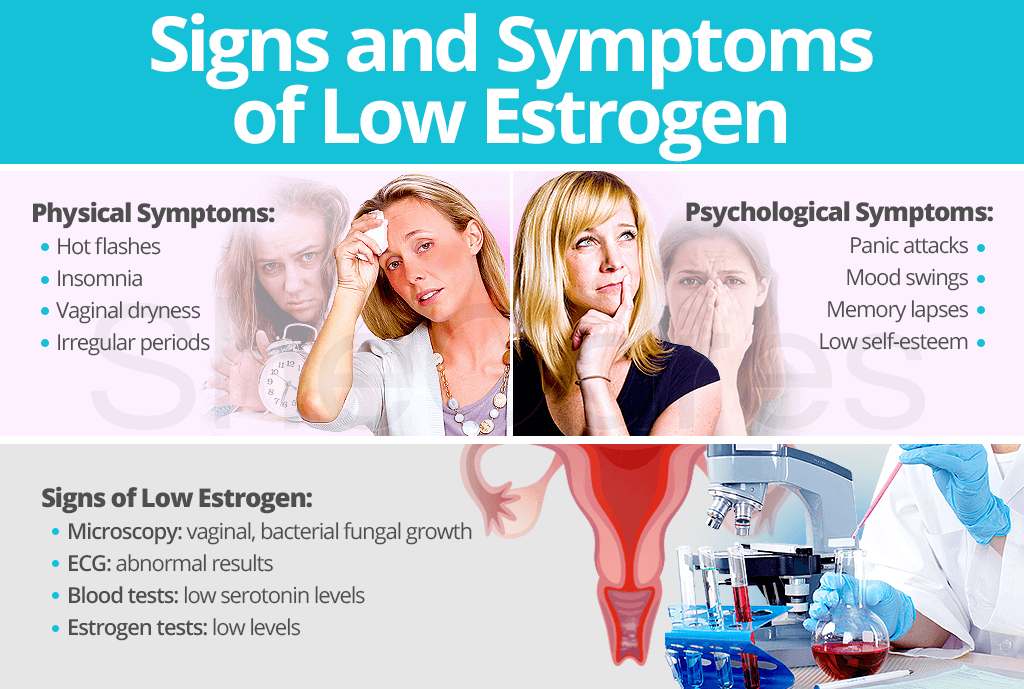

Estrogen’s Role in Skin Health: Can Low Oestrogen Cause Itchiness During Menopause

Estrogen plays a crucial role in maintaining healthy skin throughout a woman’s life. Its influence extends far beyond simply affecting appearance; it’s deeply involved in the complex processes that keep our skin hydrated, protected, and youthful. As we approach and experience menopause, understanding this role becomes particularly important as estrogen levels decline.

Estrogen’s Impact on Skin Hydration and Barrier Function

Estrogen’s effects on skin hydration are multifaceted. It stimulates the production of hyaluronic acid, a key molecule responsible for attracting and retaining water within the skin. This contributes to the skin’s plumpness and elasticity. Furthermore, estrogen influences the skin’s barrier function by regulating the production of lipids (fats) within the epidermis, the outermost layer of skin. These lipids form a protective barrier that prevents water loss and protects against environmental irritants.

A well-functioning lipid barrier is essential for maintaining skin hydration and preventing dryness, a common complaint during menopause. Reduced estrogen leads to a less effective barrier, increasing susceptibility to dryness and irritation.

Menopause can be a real rollercoaster, and the itchy skin? Ugh, the worst! Low estrogen is often a culprit, but managing these symptoms requires a holistic approach. It made me think about how managing complex conditions in children requires similar dedication, like the effective strategies outlined in this article on strategies to manage Tourette syndrome in children.

Finding the right solutions, whether it’s for hormonal changes or neurological conditions, takes time and research, but the payoff is worth it. So, back to that itchy skin – I’m still exploring options to find what works best for me during this phase.

Estrogen Deficiency’s Effect on Skin Cell Turnover and Collagen Production

Estrogen significantly impacts skin cell turnover, the process by which old skin cells are shed and replaced by new ones. A healthy turnover rate contributes to a smooth, radiant complexion. As estrogen levels decline, cell turnover slows down, leading to a buildup of dead skin cells, which can result in a dull, rough texture. Simultaneously, estrogen is vital for collagen production, a structural protein responsible for skin firmness and elasticity.

Menopause can be a real rollercoaster, and that itchy skin? Yeah, low estrogen is often a culprit. It’s amazing how much our hormones impact us! Thinking about changes in our bodies makes me wonder about other age-related issues, like the fascinating research on whether can eye test detect dementia risk in older adults. It’s all connected, right?

Back to the itchiness though – keeping hydrated and using gentle lotions has been my lifesaver!

Lower estrogen levels result in decreased collagen synthesis, leading to thinner skin, increased wrinkles, and a loss of elasticity. This contributes to the visible signs of aging often associated with menopause, and also makes the skin more susceptible to damage and injury.

Changes in Skin Composition and Increased Sensitivity and Itchiness

The combined effects of decreased hydration, slower cell turnover, reduced collagen production, and a compromised skin barrier due to low estrogen contribute to increased sensitivity and itchiness. Dry, thin skin is more prone to irritation from environmental factors like harsh soaps, fabrics, or even changes in temperature. The slower cell turnover can also lead to a build-up of irritants on the skin’s surface, exacerbating the itch.

The reduced lipid content in the skin barrier makes it more permeable, allowing irritants to penetrate more easily and trigger an inflammatory response, contributing to the sensation of itching. This increased sensitivity is a significant concern for many women experiencing menopause.

Comparison of Skin Characteristics: Pre-Menopausal vs. Menopausal Women

| Characteristic | Pre-Menopausal | Menopausal |

|---|---|---|

| Estrogen Levels | High | Low |

| Skin Hydration | Good, plump appearance | Reduced, dry, prone to dryness |

| Collagen Production | High | Low |

| Skin Elasticity | High | Low |

| Cell Turnover Rate | Fast | Slow |

| Skin Barrier Function | Strong, protective | Weakened, permeable |

| Sensitivity and Itchiness | Low | High |

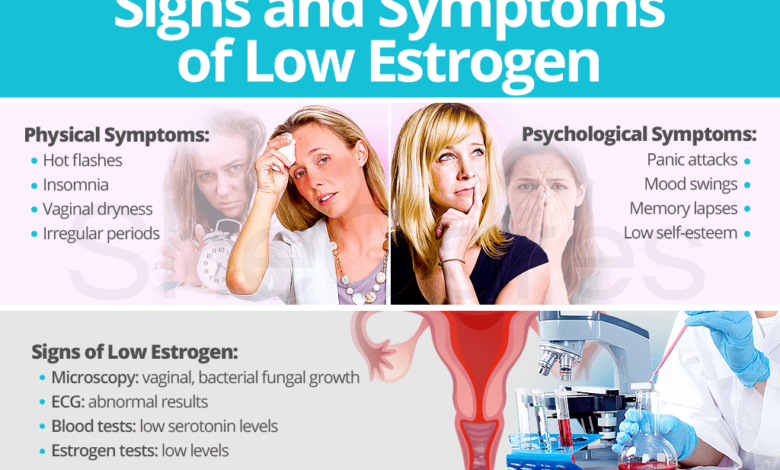

Vulvovaginal Atrophy and Itch

Menopause, marked by the cessation of menstruation, often brings about significant hormonal shifts, most notably a decline in estrogen levels. This drop in estrogen can have a profound impact on various bodily systems, and one area particularly affected is the vulva and vagina. The resulting changes contribute significantly to a common and often distressing symptom: itchiness.Vulvovaginal atrophy (VVA), also known as atrophic vaginitis, is a condition directly linked to declining estrogen levels.

It’s a natural consequence of menopause, though it can also occur in women undergoing treatments like chemotherapy or radiation that impact hormone production. Understanding the connection between low estrogen and VVA is crucial for managing the associated discomfort, particularly the persistent itch.

Vulvovaginal Atrophy: Physiological Changes and Itch

The vaginal lining, or mucosa, is richly supplied with estrogen receptors. Estrogen plays a vital role in maintaining the health and integrity of this tissue. With declining estrogen levels, the vaginal mucosa undergoes several changes. The epithelial cells, which form the protective outer layer, become thinner and less elastic. The vaginal walls lose their lubrication, becoming drier and more fragile.

The blood supply to the area diminishes, and the pH balance shifts, becoming more alkaline. This combination of thinning, dryness, and altered pH creates an environment that’s more susceptible to irritation and inflammation, leading to the characteristic itching associated with VVA. The loss of normal vaginal flora further contributes to this imbalance, increasing the likelihood of infections that exacerbate itching.

Symptoms of Vulvovaginal Atrophy

VVA manifests in a variety of ways, with itchiness being a prominent symptom. Other common symptoms include vaginal dryness, burning sensations, painful intercourse (dyspareunia), frequent urinary tract infections (UTIs), and urinary urgency or incontinence. The severity of these symptoms varies greatly among women. Some experience only mild discomfort, while others face significant challenges in their daily lives. The intensity of itching can range from a mild annoyance to a severe, debilitating sensation that significantly impacts quality of life.

Infographic: Vaginal Tissue Changes with Estrogen Deficiency

The infographic would visually depict the differences in vaginal tissue structure between a woman with normal estrogen levels and a woman experiencing estrogen deficiency. Panel 1: Normal Estrogen Levels: This panel would show a cross-section of the vaginal wall with a thick, healthy mucosal lining, abundant blood vessels, and a depiction of healthy, moist vaginal epithelium. The label would read “Healthy Vaginal Mucosa (Normal Estrogen Levels).” Panel 2: Estrogen Deficiency: This panel would show a cross-section of the vaginal wall with a significantly thinner mucosal lining, reduced blood vessel density, a dry, atrophied appearance of the epithelium, and a less defined stratified squamous epithelium layer.

The label would read “Atrophic Vaginal Mucosa (Estrogen Deficiency).”The infographic would clearly illustrate the thinning of the vaginal wall, the reduction in blood vessels, and the overall decrease in tissue volume and hydration that occurs with estrogen deficiency, directly contributing to the discomfort and itching experienced by women with VVA. Arrows could be used to highlight the key differences between the two panels, emphasizing the impact of estrogen deficiency on vaginal health.

Other Contributing Factors to Itch

Itching during menopause isn’t solely caused by estrogen deficiency. Many other factors can contribute, sometimes exacerbating the itch associated with low estrogen levels. Understanding these contributing factors is crucial for effective management. This means looking beyond hormone levels and considering other potential medical issues and lifestyle choices.

Menopause brings about significant physiological changes, and these changes can interact with pre-existing conditions or trigger new ones, leading to increased sensitivity and itchiness. It’s important to remember that a holistic approach, considering all potential causes, is often necessary for successful itch management.

Medical Conditions Exacerbating Itch

Several medical conditions can worsen itching, particularly in menopausal women. These conditions can sometimes mimic or overlap with the symptoms of vulvovaginal atrophy, making accurate diagnosis crucial. For example, eczema and psoriasis are common inflammatory skin conditions that can become more prevalent or severe during menopause. These conditions are characterized by dry, itchy, inflamed skin, and the hormonal shifts of menopause can influence their severity.

Additionally, conditions like diabetes, which affects blood sugar levels and nerve function, can also contribute to increased sensitivity and itching. Furthermore, certain medications, often prescribed for other menopausal symptoms, can have itchy skin as a side effect.

Comparison of Skin Conditions

Eczema (atopic dermatitis) and psoriasis are both chronic inflammatory skin conditions, but they differ in their underlying causes and appearance. Eczema typically presents as red, inflamed, and intensely itchy patches of skin, often with weeping or crusting. Psoriasis, on the other hand, is characterized by raised, red plaques covered with silvery-white scales. While both conditions can be itchy, the intensity and location of the itch can vary.

Both can be worsened by hormonal fluctuations, making them more prevalent during menopause. A proper diagnosis by a dermatologist is essential to determine the appropriate treatment.

Lifestyle Factors Influencing Itch

Lifestyle plays a significant role in managing itch. A poor diet lacking in essential fatty acids and antioxidants can negatively impact skin health, leading to dryness and increased itchiness. Stress, a common experience during menopause, can also trigger or worsen skin conditions through its impact on the immune system. Finally, harsh hygiene practices, such as using overly hot water or harsh soaps, can strip the skin of its natural oils, leading to dryness and irritation, thus increasing itch.

Maintaining a healthy lifestyle is therefore crucial in managing menopausal itch.

Other Potential Causes of Itch

It’s important to remember that many factors unrelated to estrogen deficiency can contribute to itching in postmenopausal women. These should be considered alongside hormonal factors for a comprehensive approach to treatment.

- Dry skin due to aging

- Fungal infections (such as yeast infections)

- Bacterial infections

- Reactions to detergents, soaps, or fabrics

- Insect bites

- Certain medications

- Underlying neurological conditions

- Kidney disease

- Liver disease

Treatment Options for Itch

Source: pinimg.com

Dealing with the persistent itch associated with low estrogen during menopause can be incredibly frustrating. Fortunately, several effective treatment options are available, ranging from hormone replacement therapies to non-hormonal approaches. The best approach depends on individual preferences, overall health, and the severity of symptoms.

Estrogen Therapy

Estrogen creams, tablets, or rings are often the first line of defense against vaginal dryness and itching related to menopause. These treatments work by replenishing the estrogen levels in the vaginal tissues, restoring their moisture and elasticity. This reduces inflammation and irritation, thus alleviating itching. Estrogen therapy comes in various forms, including vaginal creams (like Premarin), tablets (like Estrace), and rings (like Estring).

The choice of delivery method depends on individual preference and the severity of symptoms. It’s crucial to discuss the risks and benefits with a healthcare provider before starting estrogen therapy.

Lubricants and Moisturizers, Can low oestrogen cause itchiness during menopause

For some women, lubricants provide immediate relief from dryness and discomfort. These are non-hormonal options that work by adding moisture to the vaginal tissues, reducing friction during intercourse and relieving itching. Water-based lubricants are generally preferred as they are compatible with most condoms. Moisturizers, on the other hand, provide longer-lasting hydration. They are applied regularly to keep the vaginal tissues moist and supple, preventing dryness and itching in the long term.

Examples include Replens and K-Y Jelly. While lubricants offer immediate relief, moisturizers work over time to improve vaginal health.

Over-the-Counter Remedies

Several over-the-counter creams and ointments can help alleviate itching. These often contain ingredients like aloe vera, which soothes irritated skin, or hydrocortisone, a mild steroid that reduces inflammation. It’s important to use these products as directed and to discontinue use if irritation worsens. Always check with a pharmacist or doctor before using any over-the-counter medication, especially if you are taking other medications.

Self-treating can sometimes mask more serious underlying conditions.

Lifestyle Changes

Simple lifestyle modifications can also significantly impact menopausal itching. Avoiding harsh soaps, bubble baths, and scented products can reduce irritation. Wearing loose-fitting cotton underwear allows for better air circulation, preventing moisture buildup. Staying well-hydrated also helps maintain overall skin hydration, which can indirectly improve vaginal moisture levels. Practicing good hygiene, such as gently cleansing the vulva with mild soap and water, is also important.

Comparison of Treatment Options

| Treatment Option | Pros | Cons | Mechanism of Action |

|---|---|---|---|

| Estrogen Creams/Tablets/Rings | Effective for many women, addresses the root cause of low estrogen | Potential side effects (e.g., breast tenderness, bloating), not suitable for all women (e.g., history of certain cancers) | Replenishes estrogen levels in vaginal tissues, restoring moisture and elasticity |

| Lubricants | Immediate relief from dryness and discomfort, readily available | Temporary relief, doesn’t address underlying estrogen deficiency | Adds moisture to vaginal tissues, reduces friction |

| Moisturizers | Long-lasting hydration, helps prevent dryness | May not provide immediate relief, needs consistent use | Provides long-term hydration to vaginal tissues |

| Over-the-Counter Creams (e.g., aloe vera, hydrocortisone) | Soothes irritation, readily available | May not be effective for all women, potential for allergic reactions | Soothes irritated skin (aloe vera), reduces inflammation (hydrocortisone) |

| Lifestyle Changes | Simple, inexpensive, low risk | May not be sufficient for severe itching, requires consistent effort | Reduces irritation through improved hygiene and reduced friction |

Seeking Medical Advice

Source: pinimg.com

Persistent itching during menopause can significantly impact your quality of life. While many cases are manageable with self-care strategies and over-the-counter remedies, some require professional medical attention. Knowing when to seek help is crucial for effective management and to rule out any underlying medical conditions.It’s important to remember that itching is a symptom, not a diagnosis. The underlying cause could be related to hormonal changes, but it could also stem from other medical issues.

Therefore, a thorough evaluation is often necessary to determine the best course of action.

When to Seek Medical Attention

Several factors should prompt a visit to your doctor or gynecologist. If your itching is severe, persistent (lasting more than a couple of weeks), unresponsive to home remedies, accompanied by other symptoms like burning, discharge, pain during urination or intercourse, or visible skin changes (rashes, lesions), it’s time to seek professional help. Furthermore, if self-care measures don’t provide relief within a reasonable timeframe, a medical consultation is recommended.

For example, if you’ve tried over-the-counter creams and lotions for several weeks with minimal improvement, it’s advisable to consult a healthcare provider.

The Medical Consultation Process

A typical consultation will begin with a comprehensive review of your medical history, including details about your menopausal symptoms, past medical conditions, allergies, and current medications. Your doctor will likely ask about the onset, duration, and characteristics of your itching, as well as any associated symptoms. A physical examination, including a pelvic exam if appropriate, will be performed to assess the affected area and rule out other potential causes.

Menopause can be a real rollercoaster, and that itchy feeling? Yeah, low estrogen is often a culprit. Finding the right foods to help balance hormones is key, and that’s where understanding nutritional needs comes in. Check out this article on are women and men receptive of different types of food and game changing superfoods for women for some helpful tips.

Knowing what your body needs during this transition can make a world of difference in managing symptoms like those pesky menopausal itches.

Diagnostic Tests and Examinations

Depending on the initial assessment, your doctor might recommend various diagnostic tests. These could include a vaginal pH test to assess the vaginal environment, a swab for bacterial or fungal cultures to identify infections, or a skin biopsy to examine skin tissue for underlying conditions like lichen sclerosus. Blood tests may be ordered to evaluate hormone levels or check for other medical issues.

The choice of tests depends entirely on the individual’s symptoms and the physician’s assessment. For instance, if a yeast infection is suspected, a culture will be taken to confirm the diagnosis and guide treatment.

The Importance of a Comprehensive Medical History

A detailed medical history is crucial in identifying the cause of your itching. For example, a history of diabetes can increase the risk of vulvovaginal candidiasis (yeast infection), a common cause of itching. Similarly, a history of eczema or other skin conditions can predispose you to skin irritation and itching. Information about your lifestyle, such as hygiene practices and use of scented products, can also provide valuable clues.

A complete picture allows the doctor to differentiate between itching caused by hormonal changes and itching caused by other conditions.

Open Communication with Healthcare Providers

Open and honest communication is vital for effective management of menopausal symptoms. Don’t hesitate to discuss all your concerns and symptoms, even if they seem minor or embarrassing. Your doctor is there to help you find solutions, and accurate information is essential for an accurate diagnosis and effective treatment plan. Actively participate in the conversation, asking questions and clarifying any doubts you may have.

A collaborative approach will lead to the best possible outcome.

Ultimate Conclusion

Navigating menopause can feel like a rollercoaster, and dealing with persistent itchiness only adds to the challenge. Remember, you’re not alone! Many women experience this uncomfortable symptom, and there are effective ways to manage it. By understanding the underlying causes—from the impact of low estrogen on your skin and vaginal tissues to other potential contributing factors—you can make informed decisions about your treatment.

Don’t hesitate to reach out to your doctor for personalized advice and support. Taking control of your menopausal symptoms empowers you to enjoy this new chapter of your life to the fullest.

FAQs

What are some natural remedies for menopausal itching?

Some women find relief using natural moisturizers like aloe vera gel or coconut oil. Maintaining good hygiene, avoiding harsh soaps, and managing stress through techniques like yoga or meditation can also help.

Is itching always a sign of low estrogen?

No, itching during menopause can have multiple causes. Other conditions like skin allergies, eczema, or infections could be contributing factors. It’s crucial to consult a doctor to determine the underlying cause.

How long does menopausal itching typically last?

The duration varies depending on the cause and treatment. Some women experience relief quickly with treatment, while others may need ongoing management.

Can over-the-counter creams help with menopausal itching?

Yes, many over-the-counter creams and lubricants can provide temporary relief from vaginal dryness and itching. However, for persistent or severe itching, it’s best to see a doctor.